Our solution

ABC log : The unique solution for inventory and manufacturing optimization

Define your inventory classes with ABC log methodology. It is a unique improvement tool for your supply chain. Technoplane company has developped a data analysis tool that use logarithmic classes for inventory parameters calculation.

We provide daily tools that will help production and supply chain teams. We specialise in daily and weekly routines. Our tools are packages for the shop floor teams but also for the technical and quality team. We use ERP data to automate tracking files. The first step is to establish a diagnosis of your industrial performance. Then, establish guidelines for optimising daily and weekly routines. The ERP data is analysed to establish the first quick win actions.

https://www.abclog.com/wp-content/uploads/sites/4/2023/09/video-finale-2-ABC-LOG.mp4

ABC Log® Methodology

ABClog Methology uses data from the ERP system to build inventory tracking and optimisation files. The mathematical principles and tools are fairly straightforward, but it is the overall process of managing the daily data that adds complexity.

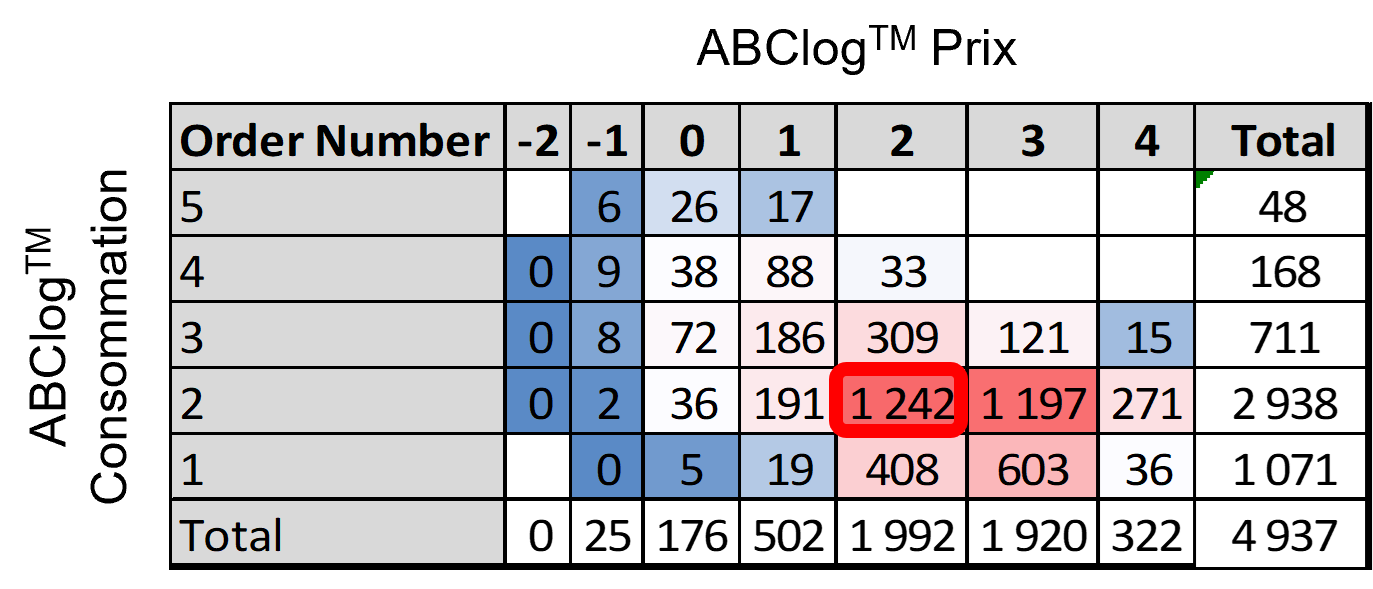

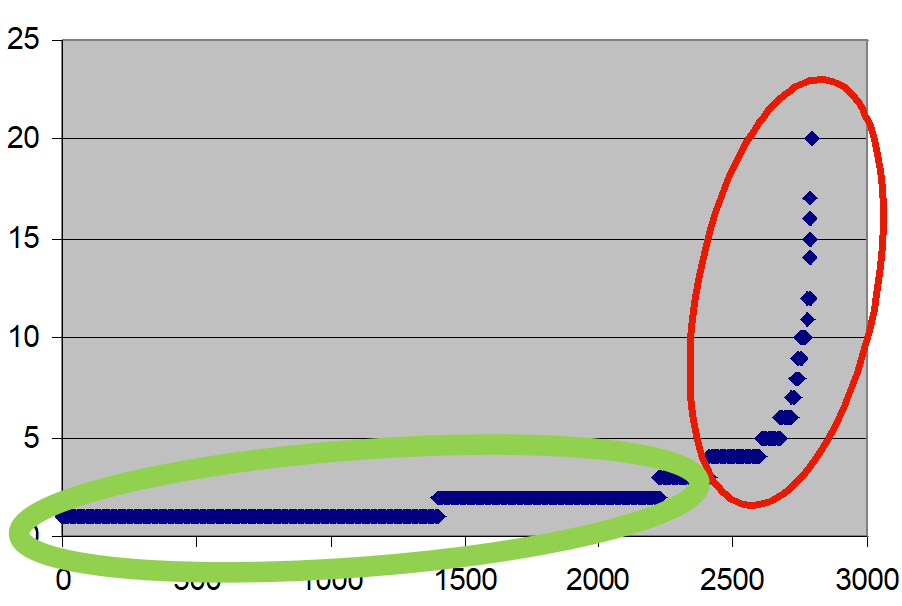

The ABC classes for item segmentation are automatically calculated with the mathematical function Log. The Log A, Log B and Log C classes are replaced by the ABClog classes with the Log10 function. This allows for a uniform approach between production and delivery sites.

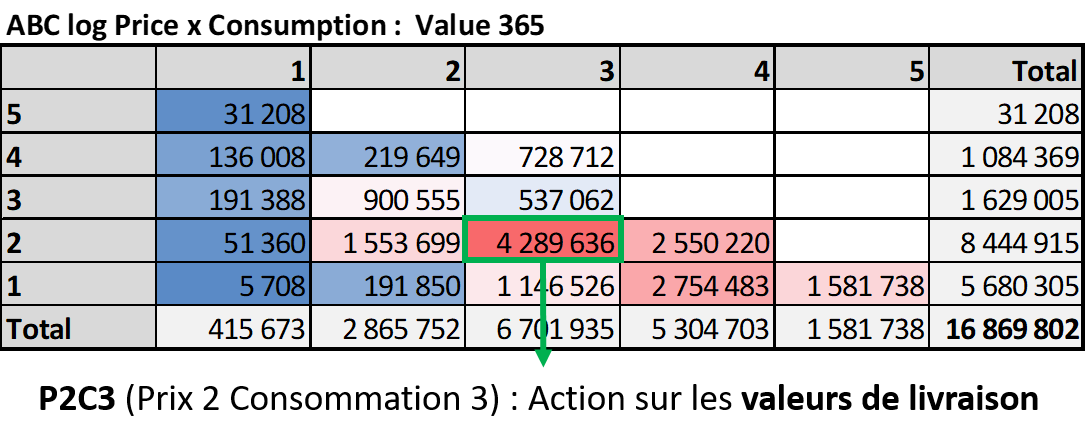

Our solution utilizes the powerful ABC Log® methodology, which leverages data from your ERP system to establish comprehensive tracking files for your supply chain and production workshop. This methodology classifies different values, such as price, consumption, and margin, enabling precise cost analysis and strategic decision-making.

Inventory Optimization Solution

Our solution offers optimized inventory management, allowing you to strike the perfect balance between meeting customer demands and minimizing inventory costs. By analyzing demand patterns and using advanced algorithms, we help you determine the optimal stock levels, reducing stockouts and excess inventory.

Enhanced Supply Chain Visibility

With our Inventory Optimization Solution, you gain enhanced visibility into your supply chain. Real-time data and analytics enable you to identify bottlenecks, streamline processes, and improve overall efficiency. By having a clear view of inventory levels, you can make informed decisions to avoid stockouts and ensure smooth operations.

Cost Reduction and Improved Profitability

Our Inventory Optimization Solution integrates seamlessly with your existing planning and forecasting systems. By combining demand forecasting, production planning, and inventory optimization, you can align your supply chain activities and improve overall operational efficiency.

Don’t let inefficient inventory management hold back your business. With our Inventory Optimization Solution, you can achieve cost savings, improve customer satisfaction, and gain a competitive edge in the market. Contact us today to learn more about how our solution can transform your supply chain management.

The unique solution for inventory and manufacturing optimization

-

ABC Log Methodology: Utilizes a unique logarithmic classification system for inventory parameters, ensuring precision and effectiveness in inventory management.

-

ERP Integration and Data Utilization: Seamlessly integrates with existing ERP systems, harnessing data for effective tracking and optimization of inventory.

-

Automated Item Segmentation: Employs Log10 function for automatic categorization of inventory into ABClog classes, streamlining the segmentation process.

-

Optimized Inventory Management: Balances customer demand and inventory costs, using advanced algorithms to maintain optimal stock levels, thus reducing stockouts and excess inventory.

-

Enhanced Supply Chain Visibility: Offers real-time data and analytics for improved transparency, helping to identify bottlenecks and optimize supply chain processes.

-

Cost Reduction and Improved Profitability: Aligns various supply chain activities like demand forecasting, production planning, and inventory optimization for increased operational efficiency and cost savings.

-

Strategic Decision-Making Support: Provides precise cost analysis through classification of values like price, consumption, and margin, aiding in informed strategic decisions.

-

Support for Daily and Weekly Routines: Specializes in tools for daily and weekly operational management, catering to both shop floor and technical teams.

-

Customized Implementation: Begins with a comprehensive diagnosis of industrial performance, followed by tailored guidelines for enhancing daily and weekly routines.

-

Competitive Advantage in Market: By improving inventory management and supply chain operations, businesses can enhance customer satisfaction and gain an edge in the marketplace.

Revolutionizing Supply Chain Management with ABC Log® Methodology

Embracing Advanced Inventory Optimization

In today’s fast-paced industrial landscape, the role of a Supply Chain Director is more challenging than ever. Balancing customer demands with cost-effective inventory management is a tightrope walk. Enter ABC Log®, a groundbreaking solution designed to transform how industries manage their supply chains. This unique methodology, developed by Technoplane, leverages the power of logarithmic classes for inventory parameters calculation, offering an unparalleled level of precision in inventory optimization. By integrating seamlessly with your existing ERP system, ABC Log® not only simplifies inventory tracking but also enhances decision-making capabilities. Its advanced algorithms analyze demand patterns, enabling Supply Chain Directors to establish optimal stock levels, thus reducing both stockouts and excess inventory.

Gaining Unprecedented Supply Chain Visibility

Visibility is the cornerstone of effective supply chain management. ABC Log® offers a solution that transcends traditional boundaries, providing real-time data and analytics for a comprehensive view of your supply chain. This enhanced visibility allows Supply Chain Directors to identify bottlenecks swiftly and streamline processes for improved efficiency. The system’s automated item segmentation, using the Log10 function, revolutionizes the way inventory is categorized. The transformation from traditional ABC classes to ABClog classes enables a uniform approach across production and delivery sites, ensuring consistency and ease of management. This level of clarity in inventory levels empowers leaders to make informed, strategic decisions, avoiding stockouts and ensuring smooth operational flow.

Aligning for Greater Efficiency and Profitability

ABC Log® goes beyond mere inventory management; it’s a strategic tool for overall supply chain excellence. By integrating demand forecasting, production planning, and inventory optimization, it aligns various aspects of the supply chain, enhancing overall operational efficiency. For Supply Chain Directors, this translates into significant cost reductions and improved profitability. The initial phase of implementing ABC Log® involves a thorough diagnosis of your industrial performance, followed by the establishment of guidelines for optimizing daily and weekly routines. Tailored to meet the unique needs of your business, it not only supports the shop floor and technical teams but also provides strategic insights for top-level management. Embracing ABC Log® is not just adopting a tool; it’s about gaining a competitive advantage in the market and driving your business towards unprecedented growth and customer satisfaction.

Transform Your Supply Chain with ABC Log® Methodology

Discover the Power of Advanced Inventory Optimization: In the realm of modern supply chain management, ABC Log® emerges as a pioneering solution, redefining the standards for inventory optimization. Rooted in the innovative ABC Log methodology, this tool harnesses logarithmic classification to meticulously manage inventory parameters. Tailored for industries seeking efficiency and precision, ABC Log® seamlessly integrates with ERP systems, elevating your inventory tracking and decision-making process. By blending technological sophistication with user-friendly functionality, it offers an unparalleled approach to inventory management, vital for dynamic market responsiveness.

Harnessing Data for Strategic Inventory Management

Unleash Enhanced Supply Chain Visibility and Efficiency: ABC Log® stands at the forefront of transforming supply chain operations with its cutting-edge features. By deploying sophisticated algorithms, our solution ensures optimal stock levels, adeptly balancing demand fulfillment with cost-effective inventory management. This strategic application of data analytics and real-time tracking mitigates risks of stockouts and excess inventory, crucial for maintaining a lean and agile supply chain. With ABC Log®, supply chain directors gain a comprehensive view of inventory flows, empowering them with data-driven insights for tactical and strategic decision-making. This enhanced visibility fosters an environment of proactive supply chain management, critical in today’s fast-paced industry landscapes.

Taking the Next Step: Engage with ABC Log®

Empower Your Business with Proven Results: Embrace the future of inventory management by choosing ABC Log®. We invite you to explore the transformative impact of our solution, as evidenced by numerous success stories from diverse industries. Our clients have witnessed tangible improvements in operational efficiency, cost reduction, and overall supply chain performance. By aligning your inventory management with ABC Log®, you position your business at the vanguard of industrial innovation. Contact us today to schedule a demonstration or to learn more about how ABC Log® can revolutionize your supply chain management strategies. Let’s embark on a journey towards enhanced efficiency and profitability together.

Benefits of ABC Log® Methodology

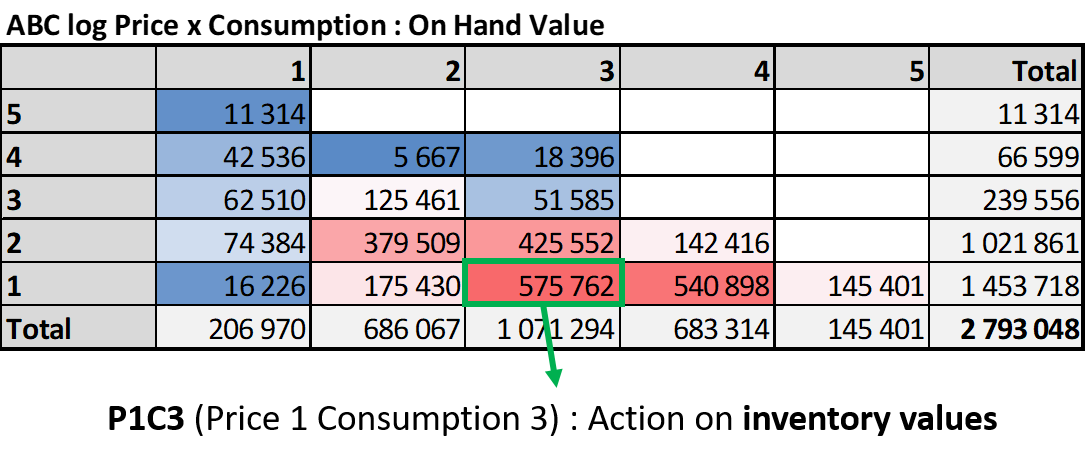

The ABC Log Price Consumption methodology offers several significant benefits for inventory management and supply chain optimization:

-

Improved Inventory Accuracy: By categorizing inventory items based on their price and consumption values, this methodology enables more precise control over inventory levels. It helps in identifying which items are crucial for the operation and which are less critical, leading to a more accurate inventory management process.

-

Cost-Efficient Inventory Management: By focusing on high-value items or those with high consumption rates, businesses can allocate their resources more efficiently. This approach ensures that capital is not tied up in low-value or infrequently used items, thereby optimizing overall inventory costs.

-

Enhanced Decision Making: The ABC Log methodology aids in making informed decisions about purchasing, stocking, and distributing inventory. Understanding the importance of each item based on price and consumption helps in prioritizing actions and strategies for supply chain management.

-

Demand Forecasting and Planning: By analyzing the consumption patterns of different inventory classes, businesses can forecast demand more accurately. This leads to better planning and preparation, especially for items that have high consumption rates and are critical to operations.

-

Risk Reduction: The methodology helps in identifying and managing risks associated with inventory, such as stockouts for high-consumption items or overstocking of expensive products. By understanding the consumption and price dynamics, companies can mitigate these risks more effectively.

-

Optimal Supplier Management: Knowing which items are most critical (high price/high consumption) can guide businesses in building stronger relationships with key suppliers, ensuring the consistent availability of these important items.

-

Streamlined Operations: The classification of inventory items according to the ABC Log method can streamline warehouse operations, as it becomes clearer how to allocate space and resources efficiently based on the value and frequency of item usage.

-

Data-Driven Insights: Utilizing data from the ERP system, the ABC Log methodology provides valuable insights into inventory trends and patterns, assisting in strategic planning and continuous improvement of the supply chain.

-

Customization and Flexibility: The methodology can be customized to fit the specific needs and dynamics of different businesses, offering flexibility in adapting to various operational models and market changes.

-

Reduced Administrative Burden: By automating the classification and analysis of inventory, the ABC Log methodology reduces the administrative workload, allowing staff to focus on more strategic tasks.

In summary, the ABC Log Price Consumption methodology brings a data-driven, efficient approach to inventory management, enhancing decision-making, reducing costs, and improving overall supply chain performance.

In today’s fast-paced industrial landscape, the role of a Supply Chain Director is more challenging than ever. Balancing customer demands with cost-effective inventory management is a tightrope walk. Enter ABC Log®, a groundbreaking solution designed to transform how industries manage their supply chains. This unique methodology, developed by Technoplane, leverages the power of logarithmic classes for inventory parameters calculation, offering an unparalleled level of precision in inventory optimization. By integrating seamlessly with your existing ERP system, ABC Log® not only simplifies inventory tracking but also enhances decision-making capabilities. Its advanced algorithms analyze demand patterns, enabling Supply Chain Directors to establish optimal stock levels, thus reducing both stockouts and excess inventory.

Visibility is the cornerstone of effective supply chain management. ABC Log® offers a solution that transcends traditional boundaries, providing real-time data and analytics for a comprehensive view of your supply chain. This enhanced visibility allows Supply Chain Directors to identify bottlenecks swiftly and streamline processes for improved efficiency. The system’s automated item segmentation, using the Log10 function, revolutionizes the way inventory is categorized. The transformation from traditional ABC classes to ABClog classes enables a uniform approach across production and delivery sites, ensuring consistency and ease of management. This level of clarity in inventory levels empowers leaders to make informed, strategic decisions, avoiding stockouts and ensuring smooth operational flow.

ABC Log® goes beyond mere inventory management; it’s a strategic tool for overall supply chain excellence. By integrating demand forecasting, production planning, and inventory optimization, it aligns various aspects of the supply chain, enhancing overall operational efficiency. For Supply Chain Directors, this translates into significant cost reductions and improved profitability. The initial phase of implementing ABC Log® involves a thorough diagnosis of your industrial performance, followed by the establishment of guidelines for optimizing daily and weekly routines. Tailored to meet the unique needs of your business, it not only supports the shop floor and technical teams but also provides strategic insights for top-level management. Embracing ABC Log® is not just adopting a tool; it’s about gaining a competitive advantage in the market and driving your business towards unprecedented growth and customer satisfaction.